About Mighty Lift - Material Handling Products

Mission Statement

MightyLift provides top quality material handling equipment and parts via creative innovation, superior customer service, reliable delivery, and sustainable development. We deliver safe, ergonomic and efficient ways for our customers to handle their products.

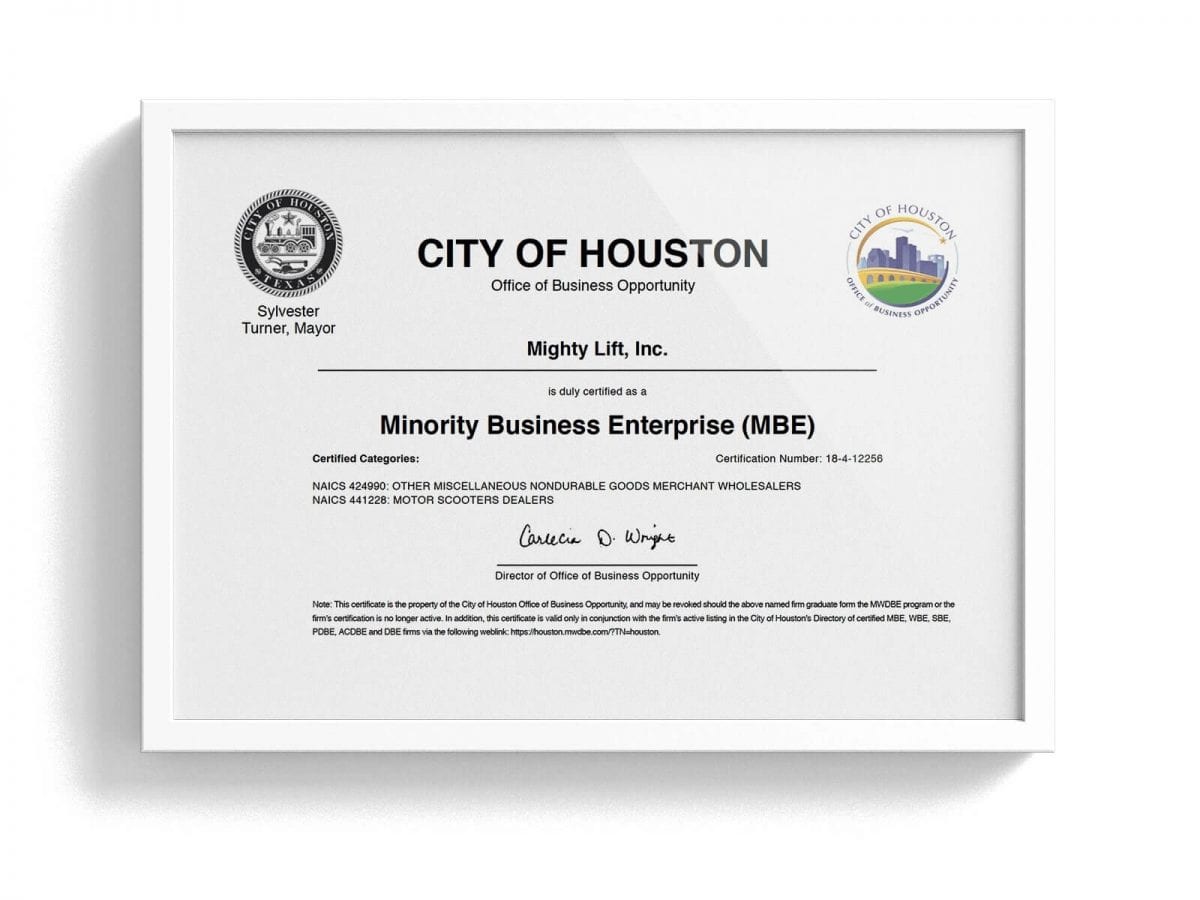

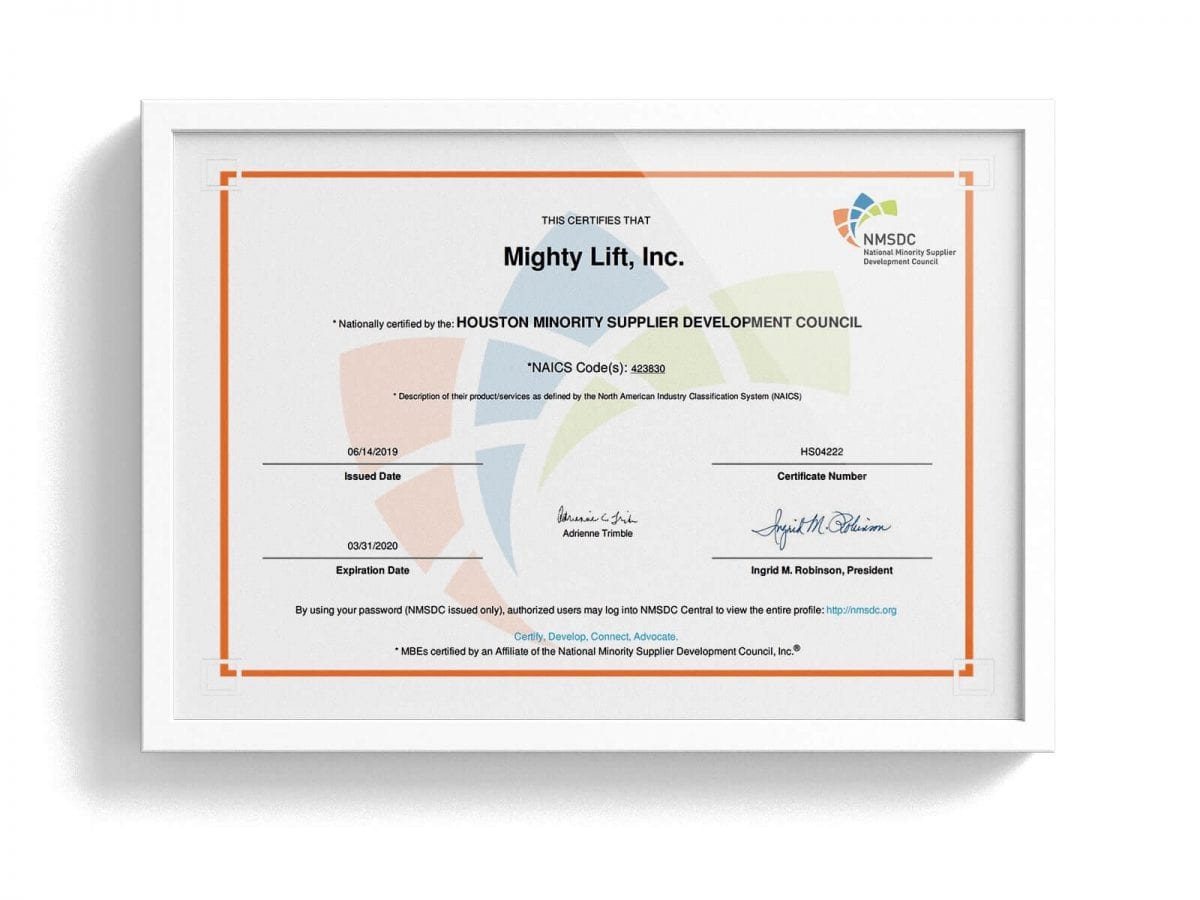

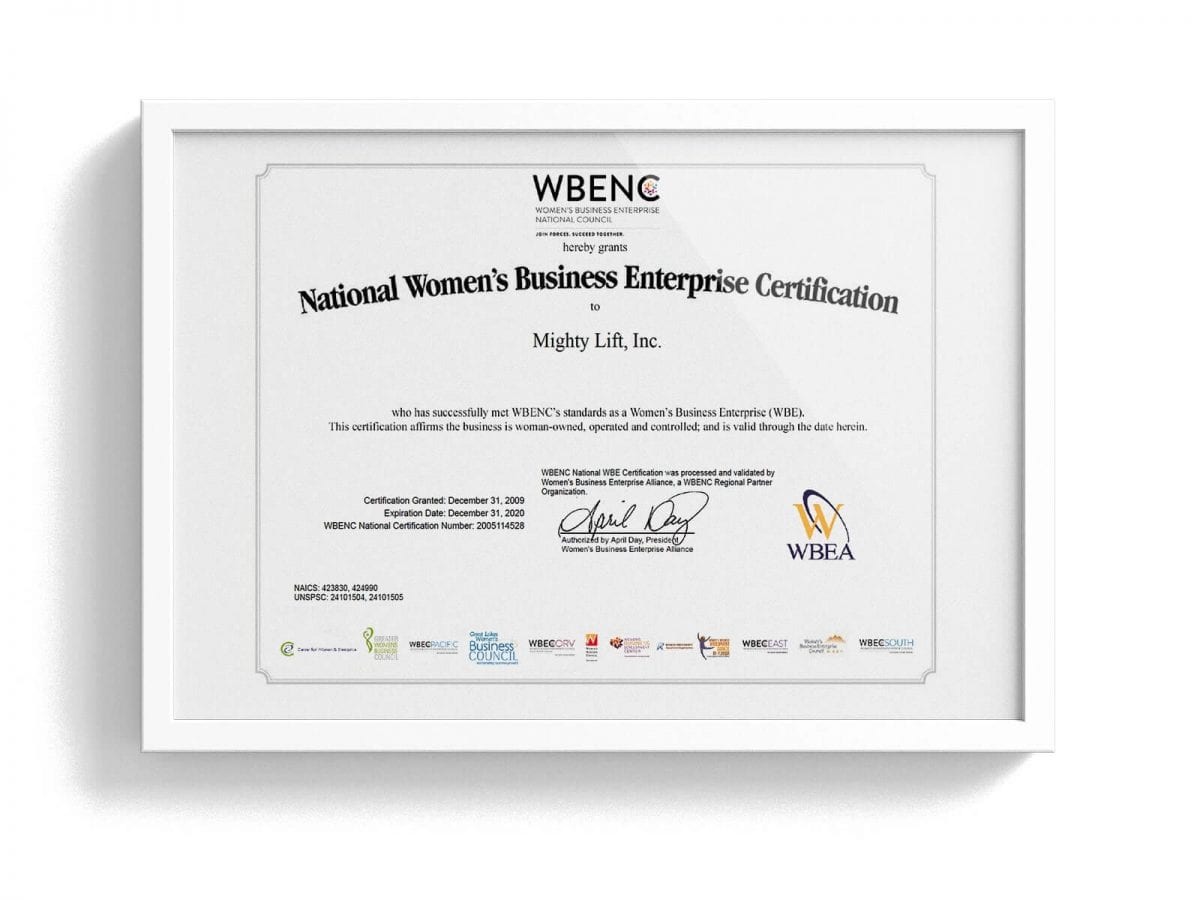

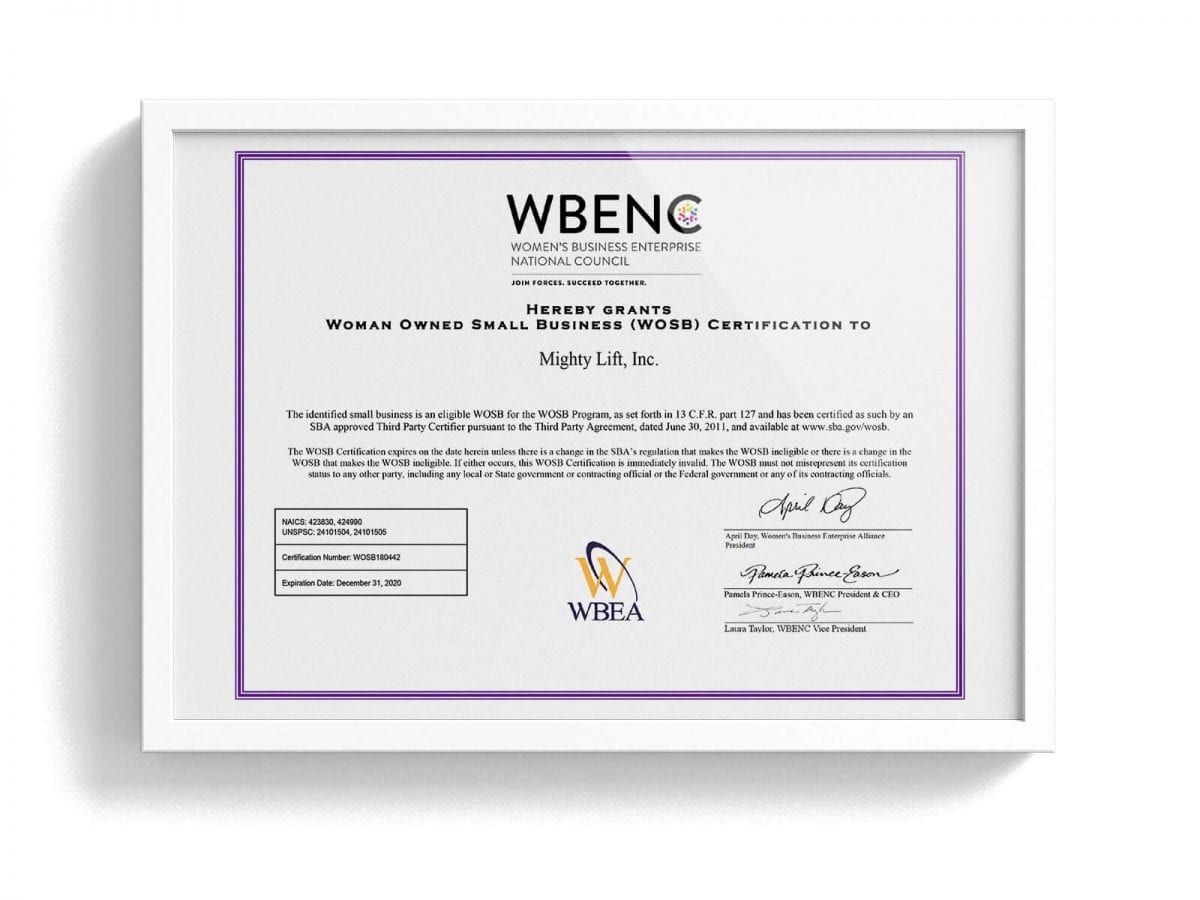

We are willing, able and committed

Helen (President of MightyLift)